The aim of the SUPP project is to create one combined and integrated robust batch process in order to stabilize and upgrade steel slag and neutralize hydrochloric acid. In addition, it this process produces high-value Precipitated Calcium Carbonate (PCC) and upgrades calcium chloride process water whilst capturing CO2 from industrial processes.

Valorization of residual components

This project offers potential options to recover, re-use and valorize components in residue streams resulting from recent research. In addition, it offers the possibility to develop new innovative processes, both process technology and process routes, and providing solutions for existing challenges regarding the continuity of operation as faced by two major industries.

Slag and CO2 produced by the Steel industry

- 50% of the produced steel slag has no applications and are piled up.

- CO2 emission reduction is essential.

Acid and brine released from the Chemical industry

- Hydrochloric acid is produced as a side product from several chemical processes, a major overproduction is foreseen in the coming decades.

- Several industrial processes produce calcium chloride containing process water, of which brines are at present often still disposed into open water. In view of environmental and upcoming scarcity aspects and upcoming restrictions, recovery and re-use of salt and water is preferred.

Industrial Synergy for PCC production

Arcelor Mittal (AM, steel Industry), AkzoNobel (AN, chemical industry), University of Leuven (KUL, knowledge institute) and Innovation Concepts (IC, SME) decided to combine their knowledge, skills and capabilities to face these challenges and find solutions.

The project partners performed research to explore possibilities and to study principles to stabilize and upgrade steel slag and neutralize hydrochloric acid during the last two years. In addition, it produces high-value PCC and to upgrade calcium chloride process water whilst capturing CO2 from industrial processes.

The objective of this project is to arrive at one combined and integrated robust batch process with synthesized feeds on lab scale, offering sufficient economic perspective.

The goals of this project are:

- To further develop and optimize the individual process steps.

- To investigate whether and, if so, how these steps can be modified to allow alignment of the steps into an integrated process.

- To perform a technical, environmental and economic assessment of the integrated process flow sheet (TRL 3 to 5).

Activities in the Steel Slag Upgrade project

- Optimizing steel slag preparation and the leaching process.

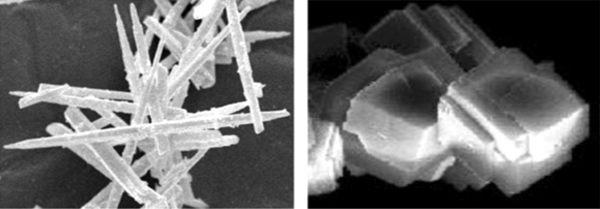

- Intensifying the CO2 contact, optimize CO2 source, PCC precipitation process and technologies.

- Development of separation of the chloride/ calcium components in process water.

- Revealing relation between required produced PCC quality and foreseen PCC application.

- Development of the integral batch process on lab scale and analysis of the economic perspective.

- Project management and sustainability assessment.

Outlook

The envisaged result of this project is the identification, development and optimisation of individual process steps. Also, to arrive at an integrated overall and optimized batch process for artificial streams on lab scale, which has been assessed from the technical, environmental and economic perspective (TRL 3 to 5; project envisages to provide readiness to start with TRL 6 development).

At the end of the project, a go-or–no-go analysis will advise the partners on the continuation of the collaboration to the next implementation phases (these phases are outside scope of this project). For example, investigating whether the integral process still performs sufficiently well in a batch process on lab scale with real process stream compositions and development of a continuous process (TRL 6). And consequently, proof that the continuous process performs sufficiently well on a representative (but not yet production) scale in a real and relevant industrial environment (TRL 7).

Partners are committed to go to a full-scale unit within 5 years if the results are positive.

You might also be interested in

Acknowledgement & partners

This project is co-funded by TKI-E&I with the supplementary grant 'TKI- Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Economic Affairs and Climate Policy.