Our flagship project Steel2Chemicals focused on the development of a closed value chain in which CO from residual gases from steel production is used as raw material in the chemical industry.

In short:

- Chemical industry needs CO as a feedstock

- Steel industry needs a solution to reduce their emissions

- Connecting them creates a a circular value chain and thus reduces CO2 emission

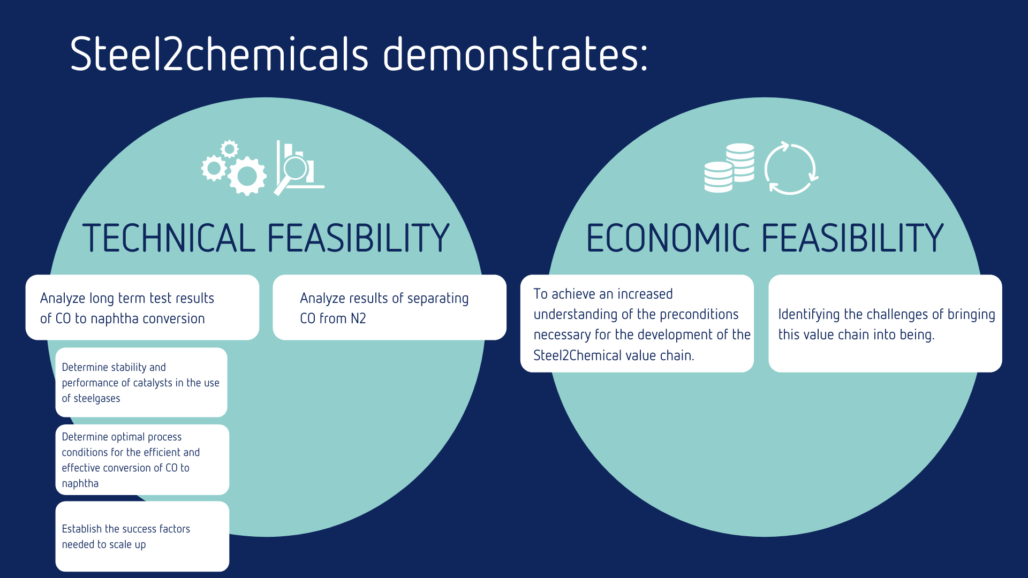

- Steel2Chemicals focuses on demonstrating the technical and economic feasibility of this value chain

Chemical industry needs alternatives for fossil resources

The chemical industry is looking for alternatives for fossil resources. This requires innovative technologies that can be used on an industrial scale, are economically feasible and can be integrated in a circular value chain. The steel industry in its turn is a major contributor to global CO2 emissions with between 1.7 and 2.5 tons of CO2 emitted per ton of steel produced. For this sector, a circular value chain offers a solution to reduce emissions.

Steel2Chemicals: a circular carbon chain

By using carbon from residual gases from steel production as feedstock for the chemical industry, the carbon is stored in a chemical product and not emitted as CO2. The raw materials in these new products can – at the end of their lifecycle – be used as a source of carbon in the steelmaking process.

Where CCS offers just a short-term solution, this concept of circular carbon will reduce the demand for fossil-based material and offer a real alternative for linear value chains.

Together with partners ArcelorMittal Ghent, Tata Steel Nederland, Dow Benelux, Ghent University and TNO, we explored the possibility of using carbon monoxide from blast furnaces for the synthesis of naphtha. This ‘synthetic’ naphtha can (partly) replace the demand for fossil naphtha used to produce e.g. ethylene, a major chemical building block and starting materials for plastics.

This is not about a little bit of CO2, it’s about millions of tons of CO2

Matthijs Ruitenbeek – DOW

The challenges of converting steel gases into synthetic naphtha

In realizing this new technology to close the carbon circle, the partners in the Steel2Chemicals project dealt with challenging issues:

- How to separate CO from CO2, N2 and other impurities?

- How to demonstrate the catalyst is suitable to convert CO to naphtha in an industrial environment?

- Which conditions make this symbiosis of steel and chemical industries technically and economically feasible?

- How to demonstrate the robustness and replication potential of this new route?

Activities Steel2Chemical project

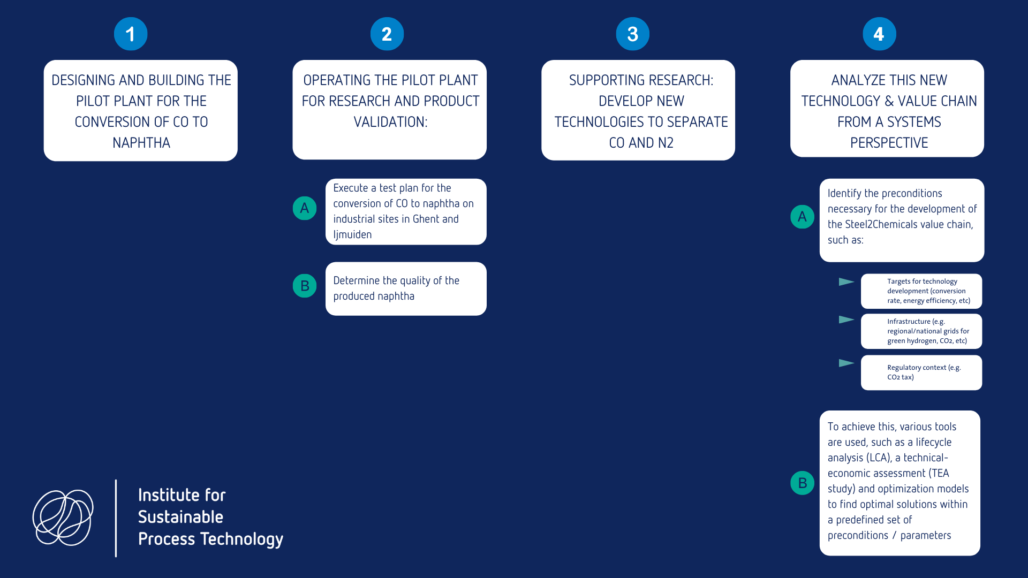

The Steel2Chemical partners are working in 4 trajectories:

Findings

Our pilot project has culminated in insightful findings that have informed the feasibility of circular carbon integration and its implications for emissions reduction:

- Mutual climate benefits: Through the valorization of steel mill off-gases as feedstock for the chemical industry, we unlock the potential for both sectors to significantly reduce greenhouse gas emissions.

- Cost-intensive process: While Steel2Chemicals holds promise, its large-scale application requires substantial investments due to challenges associated with nitrogen separation and hydrogen input.

- Alternative avenues: While the circular carbon pathway presents a viable option, alternatives such as carbon capture and utilization (CCU) or different processes for steel and chemical industries must also be considered in light of economic and political contexts.

- Synergies and possibilities: The collaborative nature of this project has laid a foundation for cross-industry, cross-border synergies, encouraging further exploration of alternative approaches.

Continuing the journey

The journey doesn’t end here. While Steel2Chemicals has illuminated significant insights, the project’s findings suggest that the feasibility of this particular circular carbon pathway is influenced by various factors. As we navigate a rapidly evolving landscape of emission reduction, energy transition, and sustainability, these insights will play a vital role in shaping the future directions of both the steel and chemical industries.

We extend our gratitude to our partners, collaborators, and stakeholders for their unwavering support and commitment to realizing a more sustainable and circular future.

For more detailed findings and analyses, we encourage you to explore our comprehensive white paper: “Advancing Circular Carbon in the Industry.” This document delves into the intricate technical aspects, economic considerations, and broader industry implications of the Steel2Chemicals project.

Also interesting to read

- Proeffabriek Steel2Chemicals: Deze technologie kan een gigantische impact hebben , Industrielinqs 2021

- Eind april beginnen eerste tests Steel2Chemicals, Industrielinqs 2021

- Vele wegen naar Groen Staal, Industrielinqs 2021

- Arcellormittal en partners op weg om koolstofkringloop te sluiten, NPT Magazine 2020

- Arcelor en Dow lossen elkaars probleem op, Financieel Dagblad 2017

You might also be interested in

Articles / Publications

Acknowledgement & partners

This project is co-funded by TKI-E&I with the supplementary grant 'TKI- Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Economic Affairs and Climate Policy.