Wet compression allows for close to isothermal conditions during compression resulting in higher compression isentropic efficiencies. It further prevents operation in the superheating zone of the working fluids of heat pumps which are associated with large energy losses and the related unacceptably high discharge temperatures which cause problems in the compressors of high temperature heat pumps.

The project

In the frame of Upgrading Low Temperature Waste Water Streams of Separation Processes with Compression (UH-20-10) project, currently under progress at TU Delft, AtlasCopco has created a prototype oil free wet compressor. At the end of this project experiments to determine its performance under high temperature heat pump conditions will be available showing its potential.

The data collected and reported in UH-20-10 concerns only the conditions at the inlet and outlet nozzles of the compressor. These data allow for validation of the global performance of the model which has been developed but is does not allow for identification of the sources of losses.

Oil free compressor for ammonia based high temperature heat pumps

This proposal aims to modify the prototype so that the variation of the internal pressure with the cavity volume can be experimentally determined. These data will allow for a detailed identification of the sources of losses during the compression process. In this way the model developed in project UH-20-10 can be validated in more detail and where needed adjusted to represent the different sources of losses more accurately. The, in this way improved, compressor model will then be integrated in the complete compression resorption heat pump model to predict the heat pump performance in high temperature applications.

In parallel a compression resorption heat pump will be designed on paper which integrates the lessons learned from the compressor prototype and modeling into a next generation commercial compressor adapted for this purpose and which also integrates the other components of the heat pump. The designed heat pump capacity will be sized similar to the present compressor prototype to about 250 kW heating power.

Results

The system has been operated with an ammonia concentration of 30% in an ammonia water solution. Compressor inlet conditions around 60 °C (this corresponds to a heat source of about 65 °C) and vapour inlet qualities in the range 50 to 90 %.

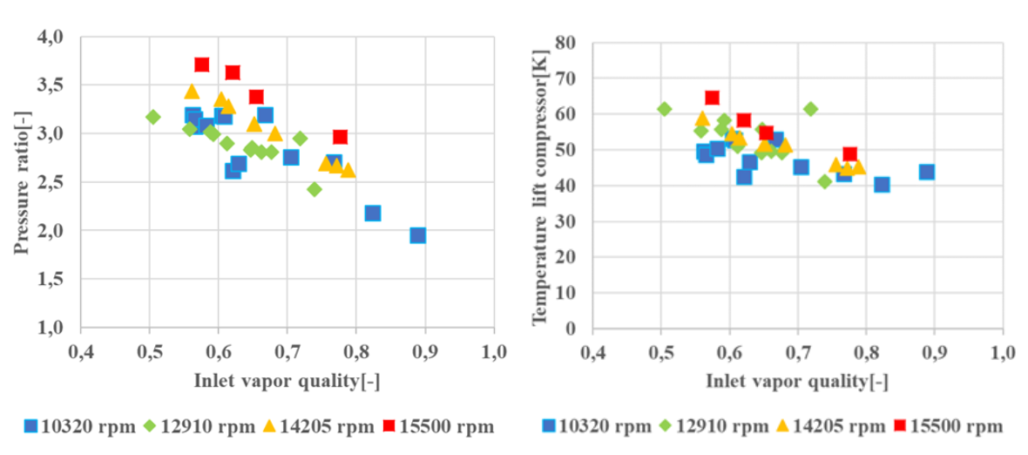

The experimental data show clearly that larger amounts of liquid at the suction port (lower vapour quality) guarantees the sealing of the leakage paths and allow for higher pressure ratios.

The figure on the right hand side shows how the vapour inlet quality affects the temperature rise as the working fluid passes the compressor. Discharge temperatures are up to 125 °C so that heat could be delivered to an application at 120 °C.

You might also be interested in

Articles / Publications

Acknowledgement & partners

This project is co-funded by TKI-E&I with the supplementary grant 'TKI- Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Economic Affairs and Climate Policy.