Today the Circular Plastics Initiative (CPI) released its Circular Plastics Roadmap, which it developed in collaboration with experts from industry and academia. The timing of the release is no accident, coming shortly after the annual ISPT Conference on 2 November and just before the DPI Annual Meeting on 17 November. The Roadmap is an interactive document that shows what steps will be needed to create a future where recycling has replaced incineration as the norm. The CPI is thus aiming to be a center of excellence for technological developments in circular plastics.

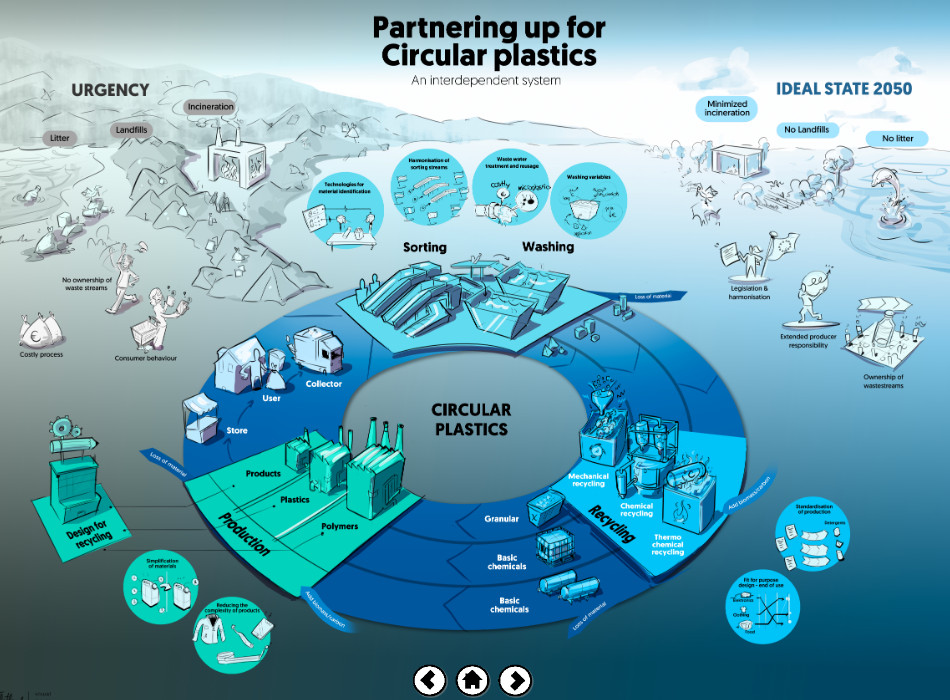

The Circular Plastics Roadmap isn’t just a timeline with milestones. It also sets out a vision for the future and shows how it can be realized. While the CPI underlines the enormous value of plastic in our society, it also acknowledges the reality of litter, landfills, and the environmental impacts that plastics have. Its ultimate goal is a future in which we have moved from a linear system of production based on fossil fuels to on based around a closed circle. In that circle, plastics will be produced from recycled materials, and CO2 emissions from the production of plastics will be drastically reduced.

The path that the Roadmap charts begins with the interdependent areas in the plastics value chain: sorting and washing, recycling, and production. For each of these, it presents the challenges and opportunities related to technological developments.

It describes 4 priorities:

- Design for and from recycling: This will involve delivering products that can be recycled over and over. In technical terms, it means in turn that the chemistry between the polymer matrix and the additives, colorants, and stabilizers must change. In addition, specific processes will have to be developed to release additives from the plastic matrix so they can be recovered. The technical challenges involved will be considerable.

- Chemical and thermo-chemical recycling: The focus here will be on creating a multipurpose platform for process monitoring in chemical-recycling technologies, coming up with separation techniques to deliver clean recyclates, optimizing the efficiency of pre-treatment technologies, and delivering recycled materials for multi-loop recycling.

- Sorting, characterization and washing: This will include assessing what techniques will be needed for optimized sorting across value chains, coming up with flexible and modular process designs for various value chains, and forecasting the value of various recyclates.

- Mechanical recycling: Among the components needed here will be a multipurpose platform for the monitoring of mechanical-recycling processes, and the development of the associated separation techniques.

Join us for collaboration

More than anything else, the Roadmap shows the strong need for collaboration among the various actors involved. That’s why the CPI is calling on industry, brand owners, recycling companies, knowledge institutes, and governments to partner with it by bringing their ideas to the table translating these into concrete project proposals. So, if you have an idea that you’d like to share, please contact the CPI’s Program Director, Ronald Korstanje at ronald.korstanje@polymers.eu.