The introduction of plant protein-based products with a good nutritional value will be a necessary step to achieve sustainability goals in the food industry. However, a transition towards more plant-based ingredients and products is now often associated with increased energy use, amongst others to purify processing streams that emerge when using more plant-based or mixed streams. The main objective of this research is to generate process configurations that are fit for the future, using much less energy per kg of ingredients or healthy and sustainable food products.

In short:

- The food industry is one of the major energy users (95 PJ/yr).

- There is a need for transition from animal proteins to plant proteins with a good nutritional value.

- Increasing energy prices, but also the protein transition and focus on lowering carbon footprint per kg product give new challenges to this sector.

- It is expected that new process configurations will lead to 30% energy reduction in 2030.

The challenge: energy savings in foods

The introduction of plant protein-based products with a good nutritional value will be a necessary step to achieve sustainability goals in the food industry. The need for this transition from animal proteins to plant proteins is now also sensed by dairy producing industries. However dairy industry has the unique position to take a different approach in ingredients production from plants using their vast know-how on milk fractionation. An approach that is efficient in energy use and does not rely on use of chemicals or organic solvents. Thus the application of dairy technology and know-how provides a wealth of new opportunities to create a next generation of plant-based ingredients and products in a much more efficient manner.

However, a transition towards more plant-based ingredients and products is now often associated with increased energy use, amongst others to purify processing streams that emerge when using more plant-based or mixed streams. For processing of these plant-based streams it is to be avoided that some of the more sustainable process routes for food processing are no longer profitable because of the high energy prices. Therefore, more research is needed to develop new or adapted processing given a set of requirements on energy consumption, ingredient functionality and carbon footprint.

New process routes need to be developed to enable sustainable food production and to cope with volatile and increasing energy prices. Energy savings in foods can be achieved through more efficient processing, the use of less chemicals and enhanced use of raw materials. The latter is extremely important, since most energy needed to make food products is consumed during primary production. Since a couple of years the Novel Process Routes project consortium started discovering these routes, focusing on reduction of the ingredients footprint by 50%. New and adapted technology configurations have been found to enable those ingredients and hence, potentially more sustainable plant-based food products.

Study the potential of water-only processes

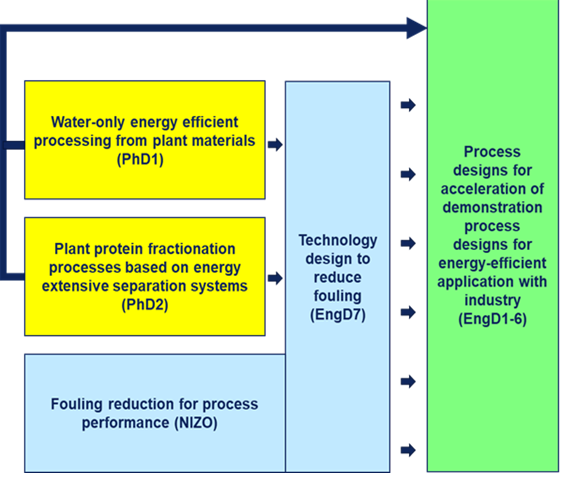

One characteristic of fractionation processes in dairy is no or limited use of processing aids or chemicals, contrary to current plant protein practices. This project therefore aims to study the potential of fractionation processes that do not rely on chemicals, which are here referred to as water-only processes. The partners in this project join forces to combine both fundamental and applied research on processing of several mixed streams originating from plant raw materials to make ingredients in an energy efficient manner and low footprint.

Besides, due to the mild character of fractionation processes in dairy industry, it can be expected that plant protein ingredients can be obtained with new functionalities compared to traditionally processed ingredients.

The main objective of this research is to generate process configurations that are fit for the future, using much less energy per kg of ingredients or (healthy and sustainable) food products.

The impact: 30% energy reduction in 2030

This novel way of processing should lead to a sustainable industry meeting the national climate and environment objectives in 2030 which could potentially also be implemented in non-food industry like pharma and chemical industry. It is expected that new process configurations will lead to 30% energy reduction in 2030. In addition, the international position of the Dutch process industry will be enhanced, both in reduced energy consumption and knowledge base.

Results

The following results are foreseen:

- Process concept for energy-efficient bulk fractionation of proteins without critical degradation of functionality, enabling further future protein transition.

- Estimated energy (PJ) reduction 30% compared to the (estimated) current state of technology that will be achieved by:

– more efficient processing through omitting and reducing use of chemicals and heat, and

– more importantly because of better use of plant raw materials and reduced losses - Extended application of sustainable food products due to removed hurdles on energy, safety and off taste

- Industrial show-cases for energy reduction technologies enabling protein transition with new process configurations incorporating energy, carbon footprint and functionality for new process streams

You might also be interested in

Acknowledgement & partners

This project is co-funded by TKI-E&I with the supplementary grant 'TKI- Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Economic Affairs and Climate Policy.