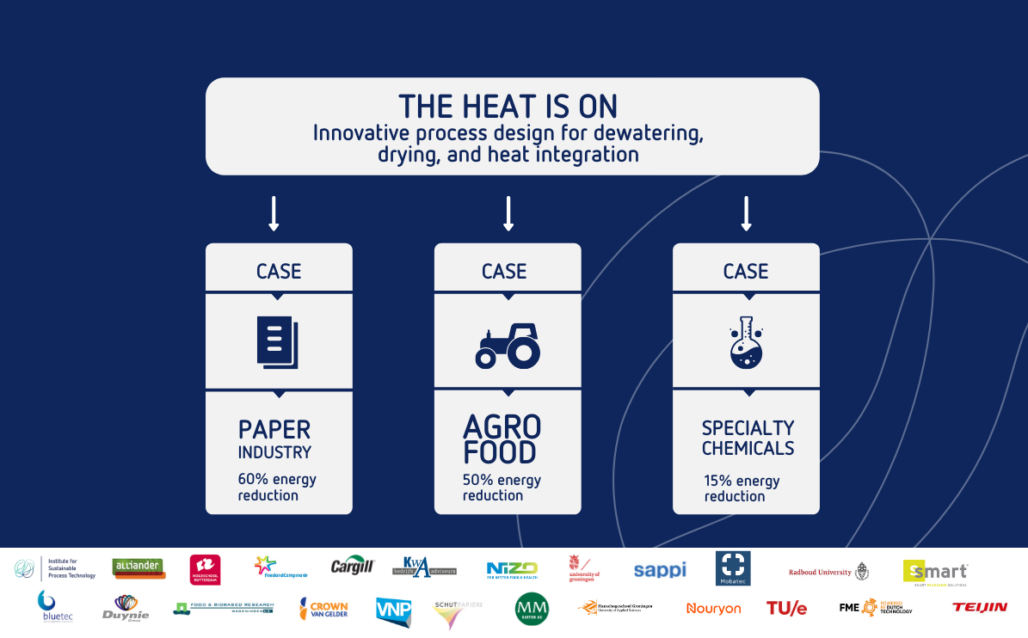

In the agrofood, paper and specialty chemicals industries 40 to 80 % of CO2 emissions is related to heat driven processes. By developing and implementing an innovative process design for dewatering, drying and heat integration, the recently granted industry driven innovation project The Heat is On will reduce fossil fuel consumption and increase energy efficiency. This leads to more than 3,0Mton CO2-reduction in 2030.

Within THIO partners in the agrofood, paper and specialty chemical industries collaborate to increase process efficiency through optimizing separation and drying processes and to increase the heat upgrading potential. Digital twinning, making an exact digital copy of a process, is used for smart process optimization and control.

Reducing CO2 emissions through innovation of heat driven processes

THIO will especially look at a combination of the following efforts:

- Efficient dewatering and drying using high solids technologies that result in 10% less water to be evaporated/dried and subsequent energy reduction.

- Combined heat integration and drying innovation concepts that result in 50% less fossil fuel consumption for drying.

- Smart manufacturing solutions that result in 10% energy savings due to improved process control.

Many innovative technologies for energy reductions in heat driven processes have been developed on lab or small pilot scale. However, due to the complexity and cohesion of processes in companies, translation to industrial application remains difficult. This project aims to accelerate the application of innovations through a case-based approach for integration into the existing process industry.

The Heat is On is supported by the Multi-year Mission-driven Innovation Program 7: A CO2-free industrial heat system.

Acknowledgement

This project is co-funded with subsidy from the Topsector Energy by the Ministry of Economic Affairs and Climate Policy.