Follow our sequel on the case results in the project Grip on Dryers – this time part 5 of 5.

Within the Grip on Dryers project, several companies that seek to innovate their drying process, teamed up with technology providers and experts from the Dutch drying community. In each case, the combined effort and knowledge exchange led to sufficient momentum and confidence for the industrial partner involved, to move beyond the idea phase and towards actual process innovation.

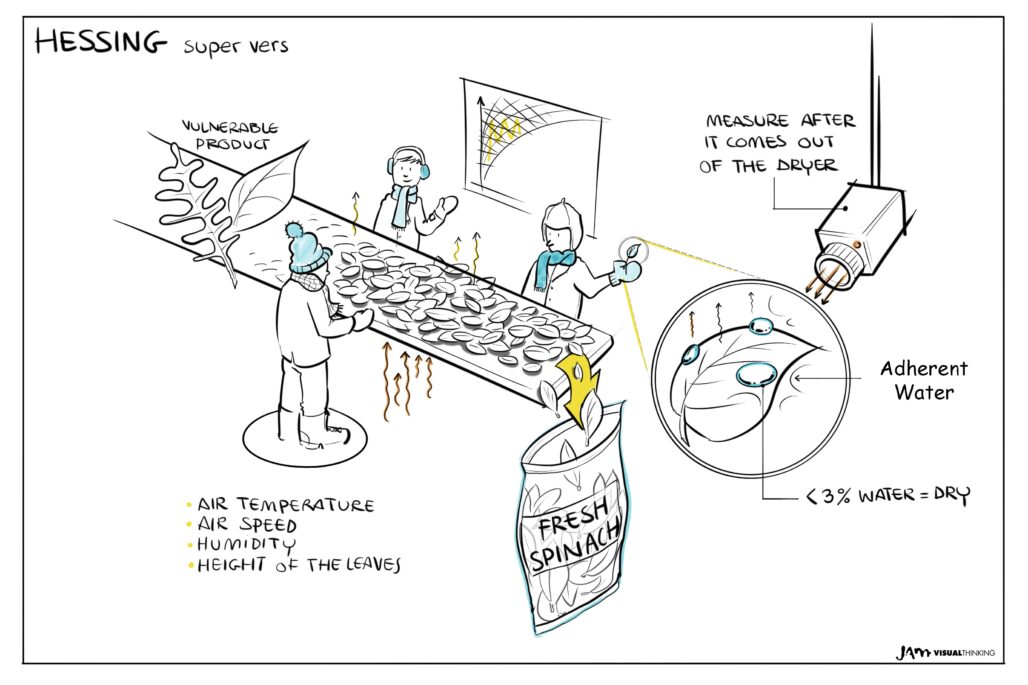

Hessing BV is a Dutch company that processes fresh raw fruits and vegetables into ready-to-cook vegetables, processed fruits and main-course salads. They supply these to supermarkets, fast food chains, wholesalers and (in-flight) catering companies.

How Hessing BV improved their drying process

For a proper shelf life of freshly packed leafy vegetables and salads, it is necessary that there is as little as possible water on the products. Therefore, after washing, the adherent water is removed via shaking, air blast and remainder with an air belt dryer. This drying should only remove the adherent water up to about 3%, without too much heating of the product. For product quality, an optimum should be found between the reduction of wet spots and the prevention of internal water loss.

In order to operate the drying process efficiently, it is necessary that relevant inline measurement data is available for process monitoring. To keep the product as cool as possible, the drying air is limited to 15°C, which requires that the in-going air is first dehumidified to a low dew point. The saturated exhaust air from the dryer goes back to the production facility, which is kept at low as 6-8°C and 95% RH by a large HVAC plant. Here lies a great opportunity to save energy by using better dehumidification and heat pump strategies.

To further improve the product quality and drying lines for several of their production locations, Hessing’s project manager Joyce Schroot teamed up with experts from WFBR, EnerQ and Ebbens Engineering. The Grip team focused on dryer robustness, possible energy savings and process monitoring and control.

After inspection of the functioning of the leafy green dryers, an image report with observations and recommendations for improved product distribution and measurement capabilities was drafted. These recommendations were later followed up by Hessing BV. Various mechanical adjustments have been made in the line to improve the belt loading homogeneity and the data registration possibilities have been adapted.

Drying capacity

At the start of the case, it was already clear that the relatively new installations in Helmond and Zwaagdijk did not meet the intended drying capacity. Hessing had the installations checked by third parties, but needed support from the Grip team for the interpretation towards a line of action. The reports of various technical providers were reviewed and summarized together with in-house measurement data. One of the deficiencies identified was that there was insufficient condensation of incoming air. Adjustments have been proposed to move towards the 2-4°C dew point and the cooling systems should be able to be regulated at dew point. This is important in order to control both drying capacity and product temperature during drying. A heat and mass balance model for the line was set-up to translate the process data to projected dryer performance.

The dryer performance (kg water/hr) can be estimated from the in and outgoing air conditions, but does not guarantee that the product is optimally dry. To steer on product quality, it would be very helpful to have an automated and inline measurement of the amount of adherent water at the end of the drying section.

The team evaluated three potential optical camera techniques and subsequent image analysis: IR emission (Thermographic camera 14-7.5um), NIR absorption (Hyperspectral line scanner 1.5 – 1.0 um), VIS reflection (normal camera, 0.8 – 0.4 um). As it turns out, in general all techniques suffer from a highly heterogeneous background scattering (the bed of leaves), vibration and fast object movement. However, in combination with data processing techniques, a feature was found that correlated specifically with the amount of adherent water as measured by the manual reference technique.

The energy performance of several air treatment alternatives were evaluated in a desk study. A closed system has the advantage over the currently employed open system that the overall coefficient of performance of the dryer increase while the load on the production facility air conditioner decreases. Precondition is that not a single swirling leaf or part of it should be recirculated from the air outflow section to the current air intake, as the evaporator coils place at the intake cannot be practically cleaned of product remains.

From a quality control point of view, it would be ideal if the fresh product would not be heated at all in the drying step, and that a maximum temperature of 7°C could be maintained throughout the whole production and logistic chain. To achieve this wet bulb temperature of 7°C, one should cool and condense the in-going air to -9°C, and heat it up to +17°C. This is not possible with ordinary air conditioning techniques, but can be achieved with a sorption wheel. Various schemes have been proposed for use of part of sorbents regeneration heat while keeping the leafy vegetables cold, dry and fresh.

Acknowledgement

This project is co-funded by TKI-E&I with the supplementary grant 'TKI- Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Economic Affairs and Climate Policy.