The scarcity of rare earth elements presents substantial challenges to the feasibility of the energy and material transition. To address these issues, a comprehensive approach combining quantitative insight and scenario thinking is essential to comprehend all potential risks faced by the process industry during these transitions. Two promising strategies have emerged to mitigate the scarcity.

The first involves the establishment of circular value chains that concentrate on collection, recycling, and design, known as the ‘Circular Oasis’ concept. The second strategy entails the implementation of transparent resource management strategies, referred to as the ‘Resource Rift’ approach. By adopting these measures, the process industry can make significant strides in overcoming the hurdles posed by rare earth element scarcity and pave the way for a more sustainable and resource-efficient future.

Rare earth elements (Ree’s) serve as unique cornerstones in our modern society, deployed sparingly for their seemingly ethereal properties across diverse modern applications. The applications where ree’s are applied include, wind mills, solar panels, and semiconductor technologies amongst many other products and devices. These elements are scarce and may form an additional barrier in the feasibility for the energy and material transition and therefore endangering our climate ambitions. During this transition, the process industry expects an increased direct use of ree’s. Take for example proton exchange membrane electrolysis, lithium battery storage and catalysts. Indirect use is also expected to increase, for instance through the increased need for renewable energy technologies to fuel electrification of the industry and hydrogen production. These are limitations that require an solution-oriented approach. This article drafts a synthesis of conversations with industrial players on the upcoming scarcity of ree’s, and two future pathways to approach this challenge.

Influencing factors for scarcity

The use of relatively abundant ree’s goes paired with many insecurities. Based on a preliminary assessment connected to this work four different type of factors were identified that impact the future scarcity of these resources.

Economic uncertainties – It becomes more expensive to mine and refine sources that are found in lower concentrations in new mines. Furthermore, the scale up of the mining industry to meet the demand is lacking. Lastly, these elements are also subjective to high price-volatility.

Geopolitical risks – Our world is connected, and ree’s prove that trade of these resources are needed as the supply of these elements and associated semi-finished products come from a short list of supplying countries, of which mainly China.

Environmental and humanitarian risks may affect the environment, nature, biodiversity and health risks and be a blockade for the opening of mining industries in the western markets.

Industry perspectives on rare earth elements

The pervasive impact of this scarcity warrants our attention; as such, we have engaged in numerous dialogues with industry professionals to gain insights into their perspectives on this pressing issue. The general consensus was that organizations are not openly active on research and innovation to mitigate the potential scarcity of rare earth elements. It is observed that the risks of scarcity are still vague. The implications this might have on the energy and material transition are unknown. As a result, there is an urgent need for increased quantitative insight into the specific factors causing scarcity and scenario explorations. More knowledge on these implications will enable where action is specifically needed.

Finding balance

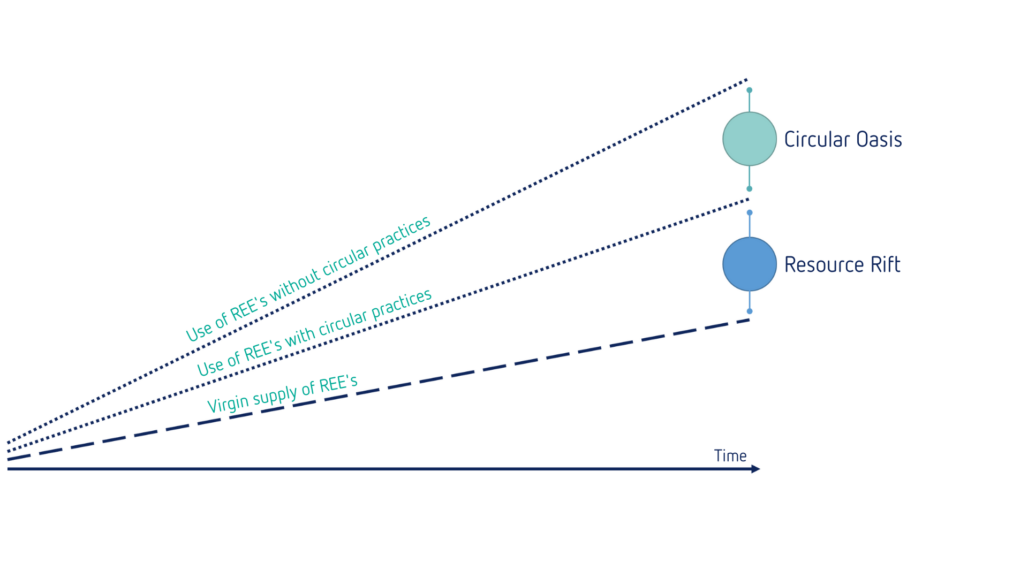

Based on conversations the scarcity of ree’s could be addressed in two concurrent routes, one being the circular oasis and secondly the resource rift. The circular oasis emphasizes the need to bring industry together, establishing new value chains and promoting circular practices for a scarce good. The resource rift implies the growing gap between world demand and supply and the need to bridge this gap through resource management. Both routes are essential for a sustainable equilibrium. In figure 1 the principles can be conceptually reviewed where the virgin supply of ree’s is depicted under a growing demand of virgin ree’s. Circular practices are able to reduce the demand for virgin materials, but will be insufficient to reach sustainability. To bridge the demand and supply new rules are needed in the playing field. Both the circular oasis and resource rift are described in a little more context.

Figure 1 – Conceptual representation of two concurrent routes to achieve sustainable use of ree’s

Circular Oasis

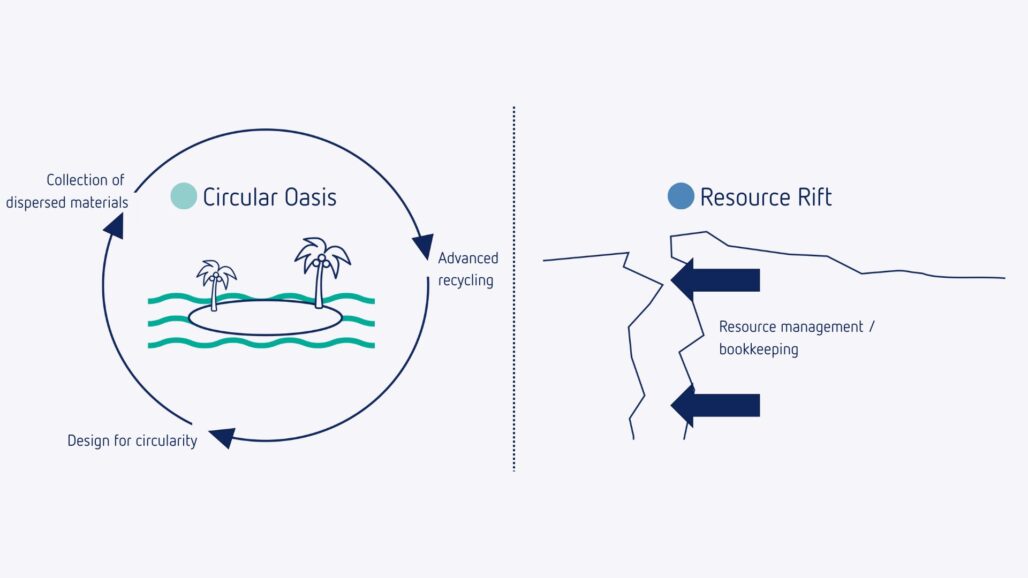

Figure 2 (left) depicts a simplification of circular value chains. Key components for approaching circularity are collection, recycling and design. The collection of dispersed materials reflects the difficulties that arise when trying to source ‘wasted’ materials. Rare earth elements find their way in multiple types of products with different lifetimes. Retrieving products with valuable metal components can become a challenge when, location, quantities and qualities of these elements are widely varying. Furthermore, not all ree’s are equal and hence worth to locate, quantify, assess and retrieve. Advanced recycling is needed to recover ree’s from waste streams. Technologies include hydrometallurgical, pyrometallurgical and resintering routes. Crucial with recycling technology will become the purity of materials, as less pure materials impact the unique characteristics of these elements, and damage the quality.

Design for circularity (D4C) principles when products are entering the market are important to ease tracing and recovery of ree’s. For example, Apple has incorporated disassembly into the design of their phones and established a disassembly facility in Breda. D4C could also address the substitution of rare earth elements by materials that are less rare. Tesla is currently doing this by switching back to EV production where rare earth elements are replaced. However, often these elements are not used in the design of products randomly, as they often fulfil earlier mentioned ethereal properties. Especially in the manufacturing of catalysts, substitution poses significant challenges.

Resource Rift

The resource rift approach (figure 2 – right) focuses on global awareness, transparency, and clarity in addressing the scarcity of ree’s. Closing the gap between rising demand and limited supply requires global insight into the present and future scarcity of these materials. Setting up resource management is a crucial tool for achieving transparency and insight into ree’s. Resource management involves planning, scheduling, and allocating resources to projects or industries. Introducing a resource management bookkeeping system on a country, European, and/or global scale allows us to gain better insight into the entire value chain of rare earth elements, including virgin supply, industrial producers, end-users, and waste processors. The knowledge acquired from enhancing global resource management of ree’s should disable unsustainable practices.

Figure 2 – Conceptual representation of the circular oasis (left) and resource rift (right)

Stay involved in the addressing of rare earth elements

In this article ree’s are discussed, however, the challenges of the material transition include a wider set of elements. Over the course of next year the Institute for Sustainable Process Technology (ISPT) will identify collaborative innovation and knowledge development needs with the industry in relation to scarcity of critical raw materials. If you wish to stay involved and raise your voice in this issue, please contact Paco Rutten.

In commission for ISPT and under the program of the Nationaal Energietraineeship, this article was jointly crafted by Franka Beijers (RVO), Eveline Winkel (Netbeheer Nederland), Nelle Kloosterboer (DNV), and Paco Rutten (ISPT), with valued input from various industrial and academic entities.